Steam Boiler

The company specializes in producing various kinds of bends, header boxes, welded pipes, membrane walls, separators and finned economizers for boilers, pressure vessels, electric power and other industries.

https://www.shuangmane.com/Steam-Boiler.html

Jiangsu Shuangma New Energy

Equipment Co. It is located in Wanshi Town, Yixing City, which is on the shore

of Taihu Lake in Wuxi City, with the Xiyi Expressway in the north and the

Ninghang Expressway in the south, which has convenient transportation and

beautiful environment. The company specializes in producing various kinds of

bends, header boxes, welded pipes, membrane walls, separators and finned

economizers for boilers, pressure vessels, electric power and other industries.

The company covers an area of 60,000 square meters, with a plant area of 50,000

square meters, a welding laboratory of 40 square meters, an exposure room of 90

square meters and a hydraulic test site of 170 square meters, with a registered

capital of 15 million yuan.

What is a steam boiler?

Steam boiler is a thermal energy conversion device used to heat water into steam, thereby generating heat and energy. A steam boiler usually consists of a boiler body, a chimney, a grate, a blower, etc., and can provide clean and efficient thermal energy.

Advantage

Our stainless steel steam boiler offers many advantages:

1. Made of stainless steel, corrosion-resistant and long life.

2. High efficiency and energy saving, fast heating speed and high thermal efficiency.

3. Highly automated, easy to operate, safe and reliable.

4. Environmentally friendly, the combustion process does not pollute the environment.

Application

Our stainless steel steam boiler is widely used in the following fields:

1. Industrial production: food processing, pharmaceutical, chemical and other fields.

2. Commercial places: hotels, schools, hospitals, etc.

3. Household use: Provide hot water, heating and other daily needs.

Why choose us?

Jiangsu Shuangma New Energy Equipment Co., Ltd. is a professional steam boiler manufacturer and industrial steam boiler company with advanced production equipment and technical team, reliable product quality and superior performance. We are committed to providing customers with high-quality products that meet international standards and focus on after-sales service to ensure customer satisfaction.

FAQ

Q1: What is the heating speed of stainless steel steam boiler?

A: Our stainless steel steam boiler has a fast heating speed and can quickly generate a large amount of heat energy to improve efficiency.

Q2: How to maintain steam boiler?

A: Regularly clean the inside of the steam boiler and check the operating status of the equipment to ensure normal operation of the equipment.

Q3: How does an electric steam boiler work?

A: An electric steam boiler works by using electricity to heat water in a closed vessel, creating steam under pressure. The steam produced is then used for heating, power generation, or other industrial processes.

Q4: Are electric steam boilers environmentally friendly?

A: Yes, electric steam boilers are environmentally friendly as they produce no emissions during operation. They are considered a clean and sustainable option for steam generation.

Q5: How often should an electric steam boiler be inspected and maintained?

A: Regular inspection and maintenance are crucial for the proper functioning of electric steam boilers. It is recommended to have them inspected at least once a year by qualified technicians to ensure safety and efficiency.

Related products:

Related products

-

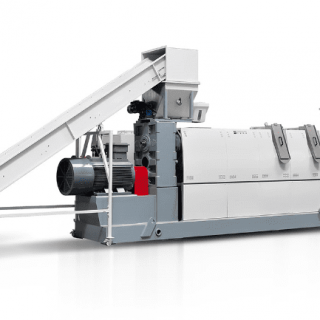

Waste plastic or Modified PE Pelletizing

Contact UsThe waste plastic or modified PE material is fed into the machine through a hopper. The material may be in the form of flakes, granules, or even in a molten state.

-

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

-

-

Capacity 1800ML Aseptic Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1800ml

Bottle Type: Aseptic-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export.

Reviews

There are no reviews yet.