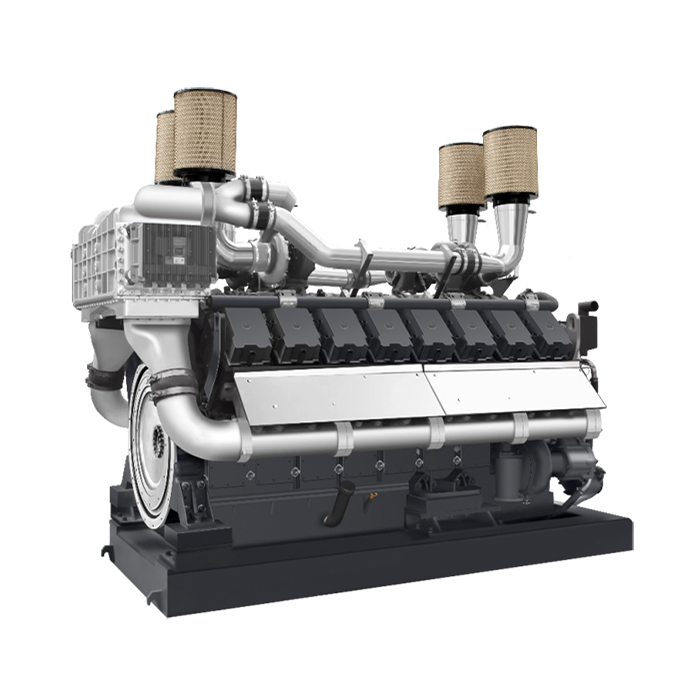

LEIQING Series High Speed Diesel Engines (1680~2660kW)

LEIQING Series High Speed Diesel Engines feature modular design for versatility and high reliability. Forged steel crankshaft, 4 valves per cylinder, and integrated cooling pistons extend service life. Quiet operation with reduced vibration. High-pressure common-rail fuel injection ensures strong power and optimal fuel economy. Equipped with high and low temperature circulating pumps for efficient cooling.

● Industrial Diesel Engine

● Power: 1680~2660kW

● rpm: 1500

https://www.wandipower.com/LEIQING-Series-High-Speed-Diesel-Engines-1680-2660kW.html

Features

● The high speed diesel engine comes with a modular design, featuring versatility for a wide range of applications, high reliability, ease of maintenance, high safety, etc.

● The crankshaft is made of forged steel, providing improved fatigue strength and wear resistance; Cooling type oscillating piston is integrally cast for extended service life.

● The front-mounted double-layer gear transmission mechanism reduces vibration, allowing for quiet running.

● The diesel engine is designed with 4 valves per cylinder with one head to achieve improved performance. Featuring the cylinder head with low swirl ratio ensures the uniformity of the air/fuel mixture, good combustion performance, low oil consumption.

● The high speed engine is equipped with two high and low temperature circulating pumps for the cooling system, which are used respectively for cooling high temperature coolant and low temperature air inlet.

● Using high-pressure common-rail fuel injection system with electronic control system in diesel engine realizes precise control in time, quantity and pressure. This makes diesel engine features strong power, optimal fuel economy, and precise emission control.

Parameters

|

Model |

Bore×Stroke (mm) |

Displacement (L) |

Rated Speed (r/min) |

Rated Power (kW) |

Max. Power (kW) |

Min. Fuel Consumption(g/kW•h) |

Oil Consumption (g/kW•h) |

Exhaust Temperature (℃) |

|

WD628E3TWD168 |

160×195 |

62.73 |

1500 |

1680 |

1848 |

195 |

≤0.48 |

≤700 |

|

WD628E3TWD182 |

160×195 |

62.73 |

1500 |

1820 |

2002 |

195 |

≤0.48 |

≤700 |

|

WD628E3TWD201 |

160×195 |

62.73 |

1500 |

2018 |

2220 |

195 |

≤0.48 |

≤700 |

|

WD708E3TWD222 |

170×195 |

70.82 |

1500 |

2220 |

2442 |

195 |

≤0.48 |

≤700 |

|

WD708E3TWD241 |

170×195 |

70.82 |

1500 |

2418 |

2660 |

195 |

≤0.48 |

≤700 |

Applications

The versatility of our high speed diesel engines makes them ideal for a wide range of applications:

– Power Generation: Reliable base-load power for industrial and commercial facilities, suitable for use as a diesel engine for gensets.

– Pumping Systems: Efficient operation for water and oil pumping in various industries

– Construction Equipment: Powering heavy machinery in construction sites

– Data center: Ensure uninterrupted power supply to the data center

Advantages

Innovative Design of Industrial Diesel Engines

The LEIQING series industrial diesel engines are engineered with an integrated and modular concept. This ensures their versatility, reliability, maintainability, and safety in industrial applications. These engines are not only designed to enhance work efficiency but also to simplify the maintenance and repair process.

High Performance

As representatives of high speed diesel engines, the LEIQING series offers models with a rated speed of 1500 rpm. These engines provide continuous and stable output under various load conditions. This high speed performance makes the LEIQING series diesel engines excellent for industrial applications that require rapid response and high efficiency.

High-Efficiency Fuel Injection System

The LEIQING series diesel engines utilize an electronically controlled high-pressure common rail fuel injection system, which enables precise control of fuel timing, quantity, and pressure. This precise control not only improves fuel economy but also helps reduce emissions, meeting increasingly stringent environmental standards.

Optimized Cooling System Design

To ensure the stability of the machine during prolonged operation, the LEIQING series diesel engines feature a high and low-temperature dual water pump circulation cooling system. This design separately cools the engine's high-temperature coolant system and low-temperature intake cooling system, effectively reducing the operating temperature of the machine and extending its service life.

Related products

-

FSH-FMI2020-B Standard Single/Double Channel Fluid Injection

Contact UsFSH – FMI2020 – B standard series of high-precision fluid dispensing / refilling system consists of a digital control box, stepper motor and one to two high precision rotary ceramic pump modules driven by step motor.

-

MA-(2~8MM)×1800MM Steel Coil Slitting Line

Contact UsMA-(2~8MM)×1800MM Steel Coil Slitting Line is mainly composed by the following components : uncoiler, guiding device

-

-

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

Reviews

There are no reviews yet.