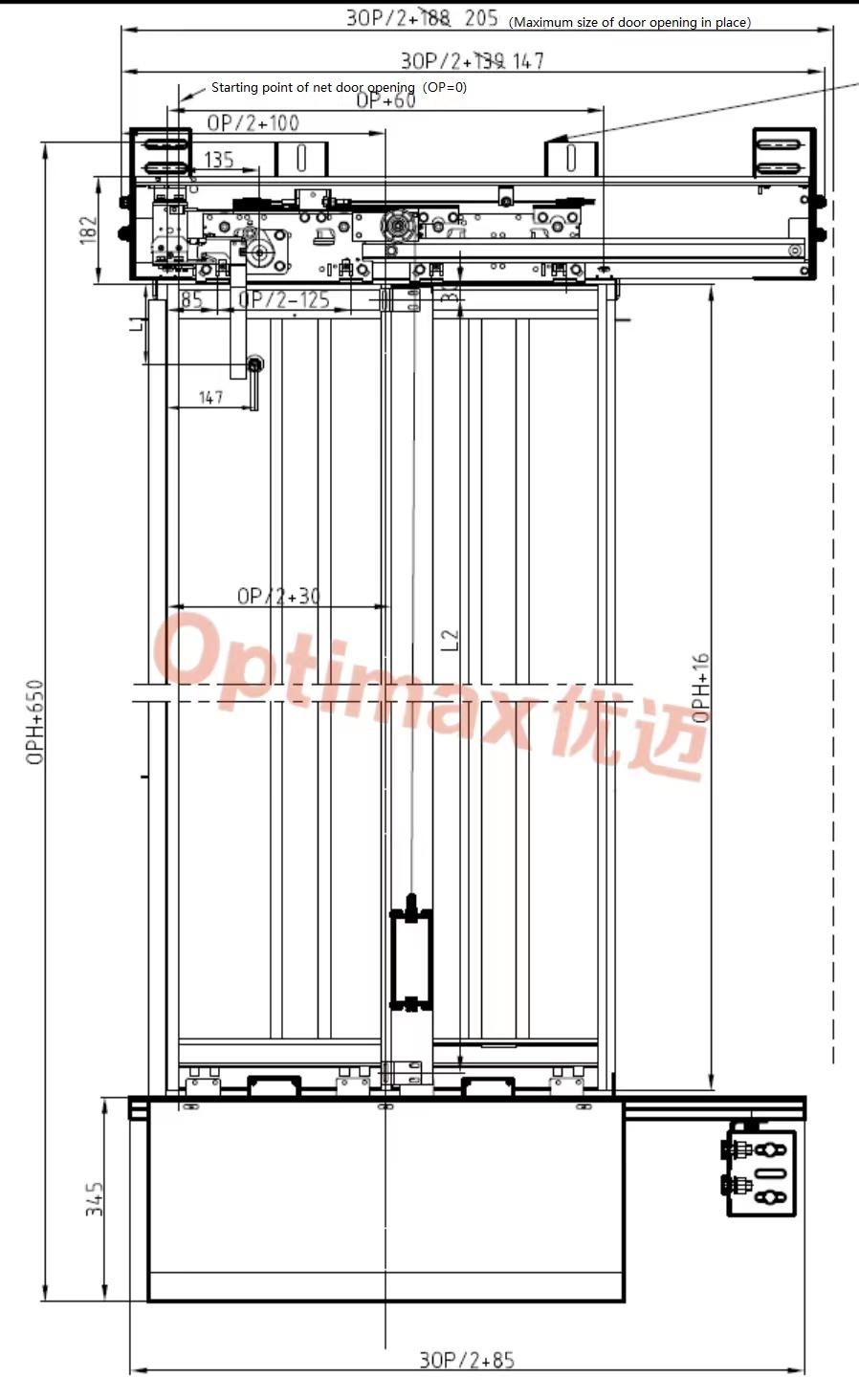

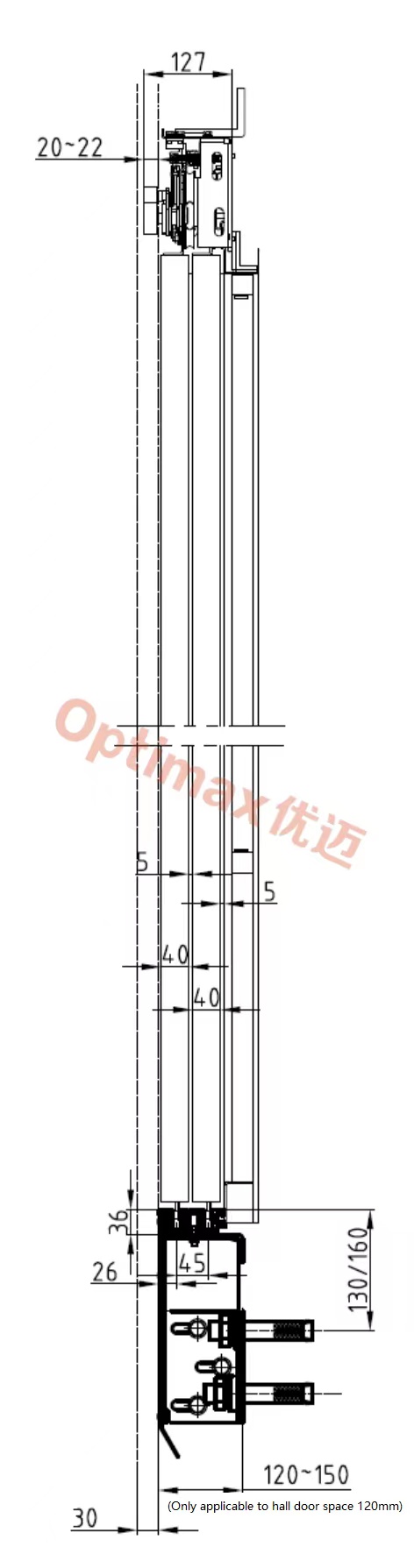

LD-2S96A-O Side Open Landing Door System

The LD-2S96A-O Side Open Landing Door System features a robust 96-mm sill design,it guarantees structural strength and stability,ensuring smooth, safe and quiet operation for passenger entry and exit.

https://www.xizi-ec.com/LD-2S96A-O-Side-Open-Landing-Door-System-with-96-sill.html

Opening type:Side Open Two Panel

Self-closing Type:Heavy hammer autistic

Sill Width:96mm

Hall Door Space:120mm

Speed: Maximum 2m/s

Match The Door Panel Material: Steel Door

OP(mm):700-1800

OPH(mm):2000-2600

This product is designed, tested and manufactured in accordance with higher standards than conventional passengers elevators. Matching door panel thickness 1.2mm, optional 1.5mm. It has strong adaptability and matches various door operators and assembly line door panels of various manufacturers in the market. It has the advantages of compact structure, easy installation and debugging. The vulnerable parts are removable for convenient maintenance.

Data Sheet Unit:mm

|

OP(Clear Opening Width) |

700 |

750 |

800 |

850 |

900 |

950 |

1000 |

1050 |

1100 |

1150 |

1200 |

1250 |

1300 |

1350 |

1400 |

1450 |

1500 |

1550 |

1600 |

1650 |

1700 |

1750 |

1800 |

|

L1=3OP/2+188 |

1238 |

1313 |

1388 |

1463 |

1538 |

1613 |

1688 |

1763 |

1838 |

1913 |

1988 |

2063 |

2138 |

2213 |

2288 |

2363 |

2438 |

2513 |

2588 |

2663 |

2738 |

2813 |

2888 |

|

OPH |

2000~2600 |

||||||||||||||||||||||

Related products

-

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

-

LFQ1300 Micro Computer Controlling Slitting Machine

Contact UsLFQ1300 Micro Computer Controlling Slitting Machine

-

3MG132G CNC automatic track grinder for ball bearing inner ring

Contact UsType: high precision bearing grinder

Abrasives: diamond wheel

Controlling Mode: CNC

Processing Mode: fully automatic

Precision: high precision

Certification: GS, CE, ISO 9001

Customisation: upon request

Place of Origin: Wuxi, China

Machining Accuracy Grade: P4/P5

External Dimensions: 2070mm*1320mm*1880mm

MOQ: 1 set

DM: 3 months

Packaging: three-ply board -

MA-(2~8MM)×1800MM Steel Coil Slitting Line

Contact UsMA-(2~8MM)×1800MM Steel Coil Slitting Line is mainly composed by the following components : uncoiler, guiding device

Reviews

There are no reviews yet.