Hob

It is used Can-making/Metal sheet Painting and Printing Ovens. According to the specifications of the printed and coated products, a large number of C-shaped buckles and rollers (made of specialized food grade imported materials) are installed on the inner bracket and edge ears of the wicket, allowing the sheet (aluminum plate) to dry and run in a separate state from the wicket, effectively avoiding the problem of dot shaped scratches and burns in the printed and coated products.

Advantages of the drying oven wicket

The above rollers and buckles allow the metal sheet (or aluminum plate) to dry and run in a separate state from the wicket, avoiding dot shaped scratches and burns caused by the original wicket.

1. Strong rigidity: The synchronization and stability of rigidity (flatness) and servo feeding and discharging effectively prevent scratches between the product and the wicket during transportation;

2. Anti-scalding: The wicket and the sheet metal store (release) heat synchronously, greatly reducing the temperature difference between the product and the wicket to avoid product scalding to the maximum extent possible.

3. Low weight: The reduction in the weight of the wicket also reduces the operating energy consumption of the drying oven, which is an energy-saving process transformation measure.

4. Longer service life

Drying Oven Wicket Application

Can-making/Metal sheet Painting and Printing Ovens

Drying Oven Wicket Description

1. The steelness and flatness of the wicket are the key components of more

than 100 pieces / minute. LONGLI wicket has been confirmed in practical use in

this field.

2. The yield resistance strength of the furnace rack is 470 Mpa

3. Electroplating adopts three nickel and one chromium process, coating

thickness 16um and potential difference 120MA

4. LONGLI Patent ¢10 × 2 hollow core tube wicket, with strong rigidity, high flatness, and light weight.

5. Two on the left and two on the right of the upper ear are angled to achieve the suspension of the coated product on the wicket, reducing the chance of scratches and scalds.

6.Total weight of 36M drying room wicket: 1.68kg/piece × 3650 pieces=6132kg

7.20 → 200 ℃ Drying conditions consume heat energy: 15m3/h (natural gas)

8. The integrated forming process adopted ensures CNC bending accuracy.

9. Using automated laser welding, the product should be controlled to meet the requirements of industrial and mining use

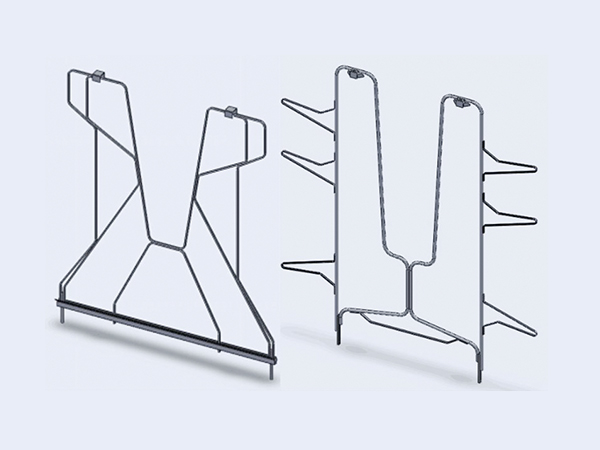

Wicket Photo Show

Related products

-

KSDC-8604A/A1 Centralized Dust Collector

Contact UsFeatures:

● Compact and reasonable structure design

● Convenient dust removal, fully automatic dust removal, to ensure the continuity and efficiency of production

● Dust collection, container loading and unloading is convenient, the connection with the filter funnel is sealed, no dust leakage

● Intelligent control, optional automatic inverter, remote linkage function

● PLC control system control, humanized design of operation panel, easy to use

● The imported high-quality polyester filter material is used, and the surface of the filter material is covered with a high-precision PTFE membrane, which has higher filtration accuracy and higher filtration efficiency -

LCTW Dynamic pass box

Contact UsThe self-cleaning transfer window allows for the transfer of materials, utensils, and other items under Class A environmental protection. Items are self-cleaned within the window before entering areas of higher cleanliness. The self-cleaning transfer window is equipped with an ultraviolet sterilization lamp and can also be fitted with a royal oxygen sterilization system according to user requirements.

-

Fluoride Removal Agent

Contact UsThe fluoride removal agent is a kind of silica-based modified ecological material specially applied to remove fluorine from natural water

-

Solid-liquid incinerator project for Ningxia

Contact UsThis project is a 10,000 tons/year hazardous waste incineration device for Ningxia, which is used for incineration and treatment of hazardous waste produced by our factory.

Reviews

There are no reviews yet.