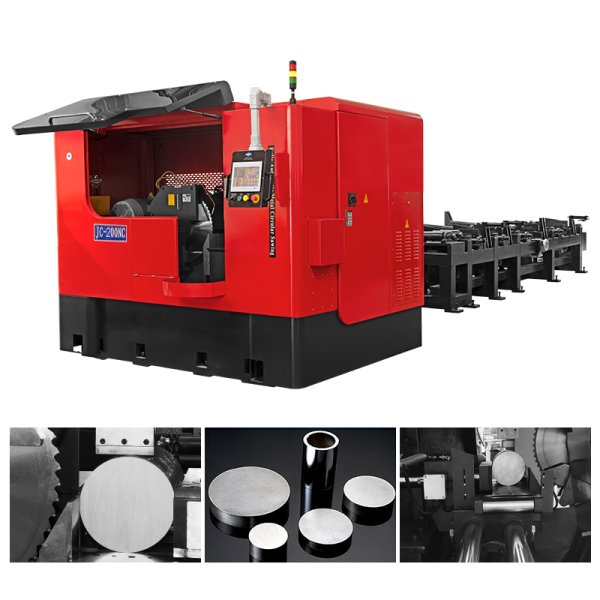

FulIy automatic metal cold sawing(horizontal)

Fast and efficient, high cutting precision, high safety, versatility, reducing manpower waste and labor intensity, suitable for a variety of industrial fields: aluminum alloy, copper, steel, etc., can also cut a variety of shapes such as plates, pipes, square steel, round steel, etc.

It can be connected to the equipment interconnection system, workshop MOM, MES or factory ERP system chain through industrial Ethernet to achieve industrial interconnection, precise production, real-time status monitoring, efficiency improvement, stable quality, product quality traceability and paperless operation.

Related products

-

Waste PE PP HDPE LDPE Plastic Bags Recycling Pelletizing Machine Line Plant

Contact UsPlastic Pelletizing Line is applicable to the rapid granulation of PE, PP, LDPF, HDPE Film, Bags, Bottles and other plastic raw materials and wastes. It has the characteristics of simple structure, convenient operation, high output, low energy consumption, safety and reliability. The output of our granulator ranges from 100 kg to 1000 kg per hour. Our machines can be customized according to your requirements.

-

OPTIMIZING CROSS CUT SAW MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

Oil-immersed transformer

Contact UsThe oil-immersed transformer is a new type of high-performance transformer with a more reasonable structure and better performance.

-

Optimizing Cross Cut Saw MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line.

Reviews

There are no reviews yet.