Explosion-proof air conditioner

This air conditioning system ensuring the safe and stable operation of electronic equipment and instrumentation in harsh offshore environments.

Description:This air conditioning system is specially designed for FPSO (Floating Production Storage and Offloading) E-HOUSE modules, ensuring the safe and stable operation of electronic equipment and instrumentation in harsh offshore environments. Key performance features include:

1. Cooling/Heating Capacity: Designed according to cabin heat load, with customizable cooling capacity to ensure stable operation of electronic equipment.

2. Air Supply: Positive pressure or 100% fresh air supply to maintain positive pressure in the cabin and prevent ingress of harmful gases or dust.

3. Temperature & Humidity Control: Constant temperature and humidity control, with temperature accuracy ±1°C and humidity accuracy ±5% RH.

4. Dehumidification Function: Dehumidification capacity configured according to cabin requirements to prevent condensation and equipment moisture damage.

5. Air Purification: Equipped with primary, medium, and high-efficiency filters to protect against dust, combustible dust, and particulate contaminants, ensuring clean cabin air.

6. Corrosion and Salt Resistance: Constructed with corrosion- and rust-resistant materials suitable for high humidity and saline offshore environments.

7. Explosion-proof Design: Compliant with ATEX / IECEx standards, suitable for IIB/IIC T1–T4 hazardous areas.

8. Control System: PLC or intelligent control supporting automatic operation, alarm monitoring, and remote control.

9. Structure & Installation: Modular or integrated design for easy transport, lifting, installation, and maintenance onboard.

10. Applications: FPSO E-HOUSE modules, offshore platform control cabins, shipboard electronic equipment cabins, and other offshore environments.

Related products

-

3MG132G CNC automatic track grinder for ball bearing inner ring

Contact UsType: high precision bearing grinder

Abrasives: diamond wheel

Controlling Mode: CNC

Processing Mode: fully automatic

Precision: high precision

Certification: GS, CE, ISO 9001

Customisation: upon request

Place of Origin: Wuxi, China

Machining Accuracy Grade: P4/P5

External Dimensions: 2070mm*1320mm*1880mm

MOQ: 1 set

DM: 3 months

Packaging: three-ply board -

-

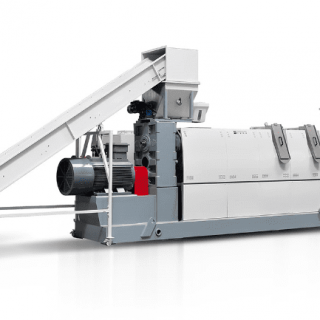

Waste plastic or Modified PE Pelletizing

Contact UsThe waste plastic or modified PE material is fed into the machine through a hopper. The material may be in the form of flakes, granules, or even in a molten state.

-

Waste PE PP HDPE LDPE Plastic Bags Recycling Pelletizing Machine Line Plant

Contact UsPlastic Pelletizing Line is applicable to the rapid granulation of PE, PP, LDPF, HDPE Film, Bags, Bottles and other plastic raw materials and wastes. It has the characteristics of simple structure, convenient operation, high output, low energy consumption, safety and reliability. The output of our granulator ranges from 100 kg to 1000 kg per hour. Our machines can be customized according to your requirements.

Reviews

There are no reviews yet.