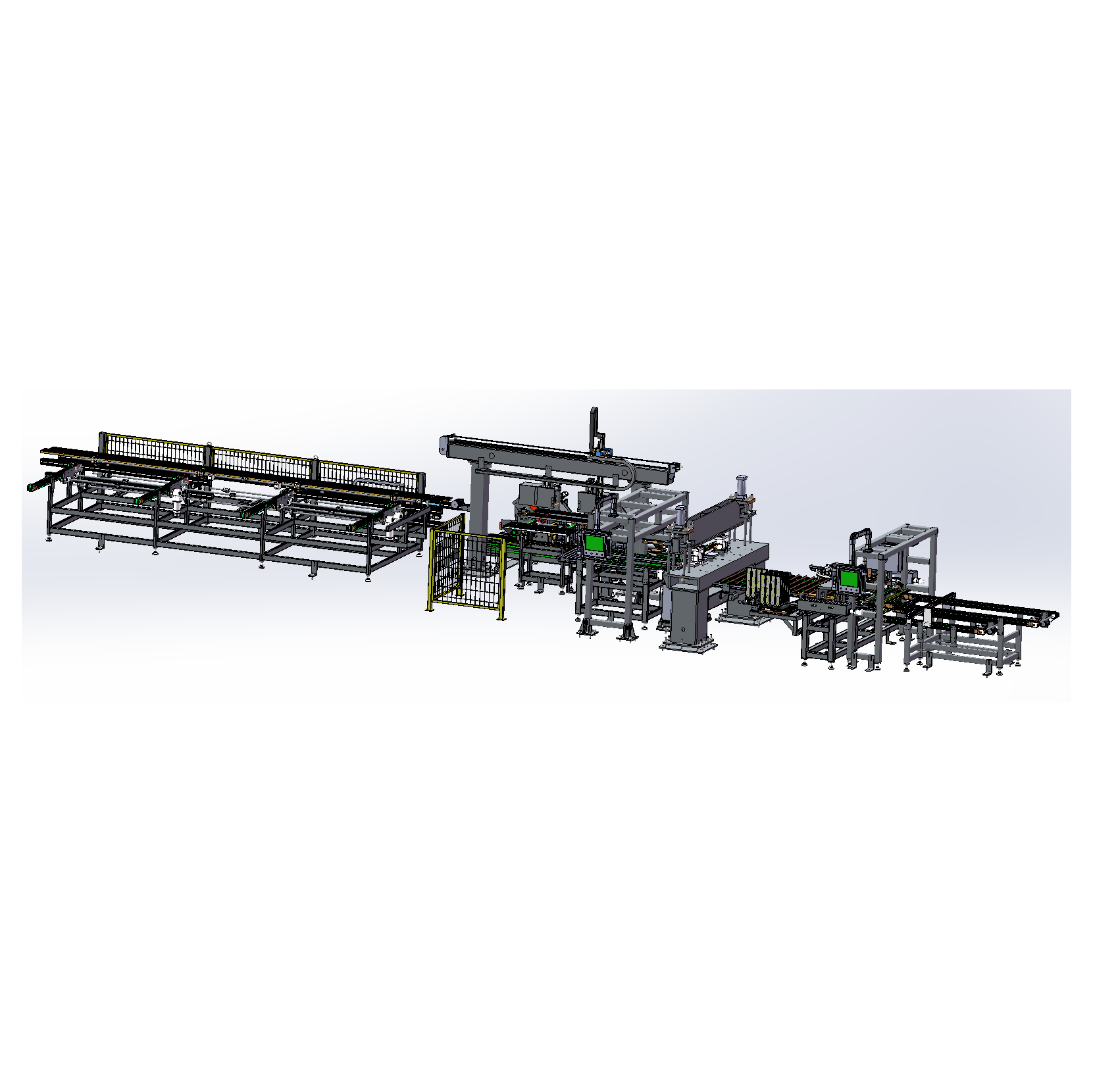

CLW-7000 automatic stamping production line of photovoltaic frame

CLW-7000 automatic stamping production line of photovoltaic frame is the 7th generation product launched by our company in 2025.

https://www.calowenauto.com/clw-7000-automatic-stamping-production-line-of-photovoltaic-frame.html

CLW-7000 automatic stamping production line of photovoltaic frame is the 7th generation product launched by our company in 2025.After more than 1 year of unremitting efforts,accumulation and reference,the company's R&D team has successfully developed anew generation of automatic stamping production line of photovoltaic frame,which has been significantly improved in production efficiency,product quality,energy saving and environmental protection, intelligent control and other aspects compared with the previous generation of production line.

Technical parameters

|

Name |

Automaticstampingproduction lineofphotovoltaicframe (longframe) |

Automaticstampingproduction lineofphotovoltaicframe (shortframe) |

|

Model |

CLW-25 |

CLW-15 |

|

Processinglengthrange(mm) |

1600~2500 |

990~1500 |

|

Processingsectionrange(mm) |

Bsidewidth:30-40,Csidewidth:10-35 |

|

|

Workingbeat(s) |

≤1.5 |

≤1.5 |

|

Angelaccuracy(°) |

±0.1 |

±0.1 |

|

Cuttinglengthaccuracy(mm) |

±0.15 |

±0.15 |

|

Qualifiedrateofprocessing |

99.8% |

99.8% |

|

Staffing(person/station) |

2.5 |

2.5 |

|

Ratedpower(kw) |

24 |

24 |

|

Externaldimensions(mm) |

16000×6000×2850 |

16000×6000×2850 |

Product advantages

1. The feeding method of sawing unit adopts the pulling material system,which improves the adaptability for twisted profiles.

2. The feeding of sawing unit is driven by electric cylinder,which effectively improves the processing quality of the workpiece.

3. The stamping molds only need to replace the punch head and inserted plate,which effectively reduces the costs.

4. Intelligent detection including length,mounting hole,bending,twisting,aluminium angle and water leakage hole detection.

5. Five sets of aluminium angle cartridges are set on one side of short frame stamping unit,and the aluminium angle capacity is greatly increased.

6. The finished products and defective products are automatically separated by upper and lower double-layer conveyor belt.

Related products

-

Optimizing Cross Cut Saw MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

UT 1.6523/8620/20CrNiMoA Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Blockund Bar

Contact Us1.6523 Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Block/Round Bar

-

Used NSC Schlumberger FM7N Spinning Machine

Contact UsThe company was established in Zhangjiagang, Jiangsu, China in 2005 .Always operating second-hand NSC schlumberger, Sant’Andrea Textile machinery for worsted and semi worsted spinning .

-

Waste PE PP HDPE LDPE Plastic Bags Recycling Pelletizing Machine Line Plant

Contact UsPlastic Pelletizing Line is applicable to the rapid granulation of PE, PP, LDPF, HDPE Film, Bags, Bottles and other plastic raw materials and wastes. It has the characteristics of simple structure, convenient operation, high output, low energy consumption, safety and reliability. The output of our granulator ranges from 100 kg to 1000 kg per hour. Our machines can be customized according to your requirements.

Reviews

There are no reviews yet.