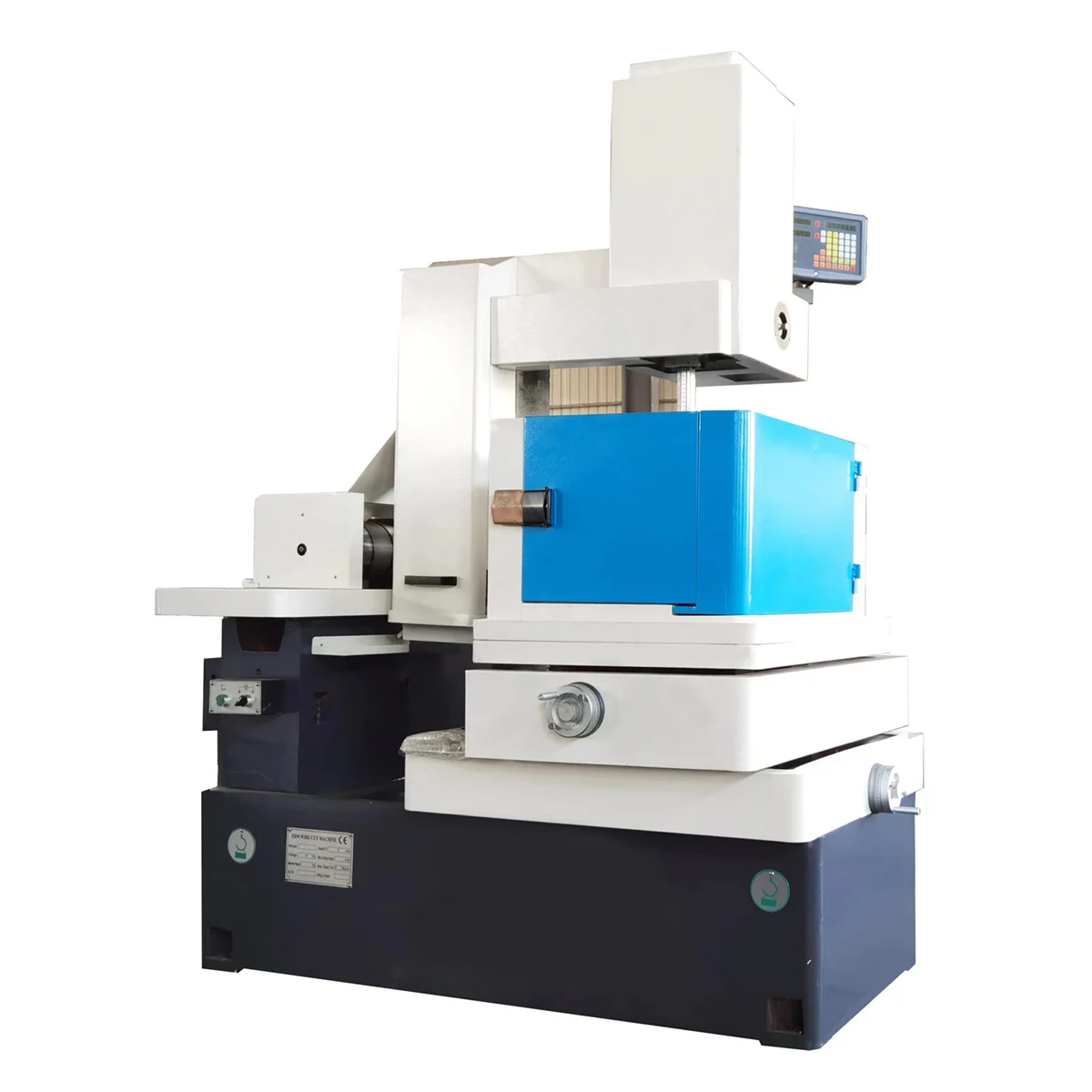

BF350C BF450C Heavy Dudy High Precision Edm Wire Cut Machine

Robust frame with “C” mast.

With height adjustable diamond guider.

Four axes independent (X/Y/U/V) work;

Taiwan linear rail, Grade P or H, Ball screw. C2 or C3.

Special Tensioning mechanism for molybdenum wire, keep stable cutting.

Stepper motor is standard, Servo motor is optional.

Tolerance can keep in 0.005mm, Roughness Ra 0.8.

Multi-cut EDM Wire Cutting Machine (C type)

Robust frame with "C" mast.

With height adjustable diamond guider.

Four axes independent (X/Y/U/V) work;

Taiwan linear rail, Grade P or H, Ball screw. C2 or C3.

Special Tensioning mechanism for molybdenum wire, keep stable cutting.

Stepper motor is standard, Servo motor is optional.

Tolerance can keep in 0.005mm, Roughness Ra 0.8.

Technical Parameters:

| Model | BF320C | BF350C | BF400C | BF450C |

| Working table size (mm) | 500×720 | 550*780 | 580×820 | 650*880 |

| Table travel (X/Y) (mm) | 320×400 | 350×450 | 400×500 | 450×550 |

| Max.cutting thickness (mm) | 400 | 300 | 400 | 300 |

| Max. load on workingtable (KG) | 400 | 500 | 600 | 800 |

| Travel size (U/V) (mm) | 24×24 (±3°) ( optional: 30×30 75×75 135×135) | |||

| Wire Dia. (mm) | (Molydbenum wire) φ0.10~0.22 ( special 0.25, 0.30mm) | |||

| Wire speed (m/sec) | 2.0-11.0 | |||

| Max. cutting speed (mm2/min) | 160-180 | |||

| Max.cutting angle | ±3°/80mm ( ±6° ±15° ±30°degree is optional) | |||

| Process accuracy (mm) |

(Multi-cut): 10×10×30(Square)≤0.008; (One time-cut)≤0.012; (Multi-cut)(Octagon)≤0.01; (Straightness)≤0.008/50mm; |

|||

| Roughness (Ra.um) | Multi-cut):Ra≤0.8, Single-cut):Ra≤2.0 | |||

| Driving motor | Step motor / AC servo motor* (Optional) | |||

| Guide rail and ball | Precision ball screw/Linear rail | |||

| Tension system | three stage(0/1/2)tension adjustable | |||

| Power supply | 380V/50Hz, 2.5kw | |||

| Weight (kg) | 1600 | 1700 | 1800 | 2000 |

| Dimension (mm) | 1700*1400*1900 | 1700*1500*1900 | 1900*1500*1900 | 1900*1550*2000 |

Company & Workshops

BOFENG Machinery is a group with 4 factories. BOFENG has about 60000 square

meter work shop.

Production Equipments

The main parts of our machines are processed by cnc machine. We have gantry

type cnc milling machine, cnc vertical machining center, gantry type cnc

grinding machine, cnc laser cutting machine, cnc bending machine, cnc shearing

machine.

Test & Inspection

All machines will be tested before shipment.

Package & Delivery

Related products

-

Oil-immersed transformer

Contact UsThe oil-immersed transformer is a new type of high-performance transformer with a more reasonable structure and better performance.

-

Capacity 1800ML Aseptic Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1800ml

Bottle Type: Aseptic-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export. -

-

Reviews

There are no reviews yet.