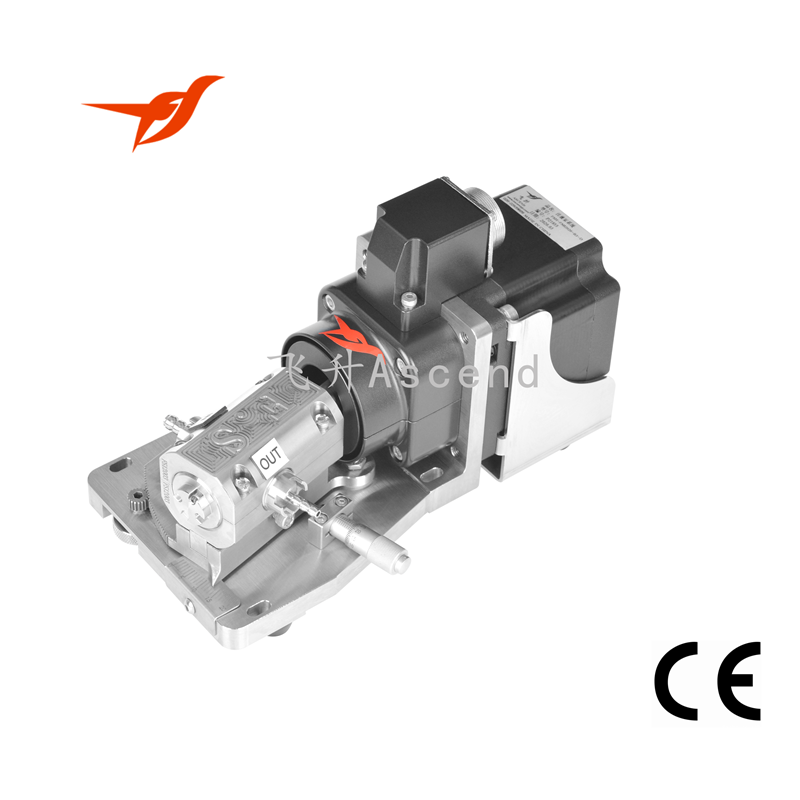

FSH-FMI2020-B Standard Single/Double Channel Fluid Injection

FSH – FMI2020 – B standard series of high-precision fluid dispensing / refilling system consists of a digital control box, stepper motor and one to two high precision rotary ceramic pump modules driven by step motor.

FSH – FMI2020 – B standard series of high-precision fluid dispensing / refilling system consists of a digital control box, stepper motor and one/two high precision rotary ceramic pump modules driven by step motor.

https://www.ascendtechs.com/FSH-FMI2020-B-Standard-Single-Double-Channel-Fluid-Injection.html

Specification:

Technical Parameters:

System Features:

Corrosion resistance to acid or alkali fluid or chemical reaction. Compatible

with most fluids.

Elastic sealing approach for fluid inlet and outlet provides more reliable

sealing.

Maintenance free design. Almost zero wearing parts. Helps customers maximize

machine uptime. Minimize machine downtime and maintenance cost.

Dispensing and loop operation mode. Forward and reverse direction motion

mode.

Rich control interface selections. Medium / high torque motor selection.

Wearing resistant. No moving sealing O-ring (tens of millions of operation

without wearing)

Ceramic pump modules can be customized per customer's requirements.

Typical Applications:

Lithium battery electrolyte injection

Fluid drug dispensing or filling

Reagent dispensing or filling

Spraying or coating

Silicone oil atomizing and spraying

Contact lens dispensing

Flavor, essence and liquid vitamin additions

Related products

-

Waste PE PP HDPE LDPE Plastic Bags Recycling Pelletizing Machine Line Plant

Contact UsPlastic Pelletizing Line is applicable to the rapid granulation of PE, PP, LDPF, HDPE Film, Bags, Bottles and other plastic raw materials and wastes. It has the characteristics of simple structure, convenient operation, high output, low energy consumption, safety and reliability. The output of our granulator ranges from 100 kg to 1000 kg per hour. Our machines can be customized according to your requirements.

-

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

-

MA-(2~8MM)×1800MM Steel Coil Slitting Line

Contact UsMA-(2~8MM)×1800MM Steel Coil Slitting Line is mainly composed by the following components : uncoiler, guiding device

-

Used NSC Schlumberger FM7N Spinning Machine

Contact UsThe company was established in Zhangjiagang, Jiangsu, China in 2005 .Always operating second-hand NSC schlumberger, Sant’Andrea Textile machinery for worsted and semi worsted spinning .

Reviews

There are no reviews yet.