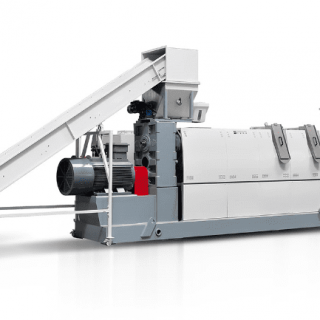

Main Parameters for CJWH Middle Torque Series Twin Screw Extruders

CJWH series twin-screw extruders mainly focus on middle level customers with improved requirement for quality and efficiency.This series machine equipped with local made middle torque & high speed gearbox, the technology, configuration, performance and quality in the domestic leading level with competitive efficiency

Suzhou Jwell Machinery Co., Ltd.is an important development strategic center

and manufacturing base of Jinwei Machinery. It is located in Chengxiang

Industrial Park, Taicang, Suzhou, and is 30 minutes' drive from Shanghai

Hongqiao Airport. It covers an area of 20 hectares, with an indoor area of

120000 square meters. It is equipped with advanced CNC machining base for parts

and standard assembly workshop. With more than 1000 employees, it has a

high-quality design and development team and an experienced team of mechanical

and electrical commissioning engineers.

The company focuses on plastic pipe and sheet film extrusion equipment

manufacturing and various professional technical services, and carefully

manufactures plastic extrusion equipment that meets the needs of global users,

of which foreign trade exports account for more than 75%. Strict design, strict

standardized manufacturing process and perfect after-sales service guarantee

system provide users with efficient, energy-saving and high-quality production

line equipment and considerate services.

Contact whatsapp: 138 1703 9977 / 139 1685 8896 / 139 1887 6278 / 134 7257 0215 / 158 0622 6900

Email: salbn@jwell.cn

Summary

CJWH series twin-screw extruders mainly focus on middle level customers with improved requirement for quality

and efficiency.This series machine equipped with local made middle torque & high speed gearbox, the technology, configuration, performance and quality in the domestic leading level with competitive efficiency

| Model | Diameter(mm) | L/D | Screw speed(rpm) | Motor power(KW) | Torque pershaft(N.m) | Specific torque(T/A³) | Capacity range(kg/hr) |

| CJWH25 | 26 | 24~68 | 600 | 11 | 87 | 9 | 20~40 |

| CJWH35 | 35.7 | 24~68 | 600 | 30 | 235 | 9 | 75~150 |

| 1000 | 45 | 9 | 110~220 | ||||

| CJWH40 | 41.3 | 24~68 | 600 | 45 | 357 | 9 | 110~220 |

| 1000 | 75 | 9 | 190~380 | ||||

| CJWH52 | 51.7 | 24~68 | 600 | 90 | 692 | 9 | 220~440 |

| 900 | 132 | 9 | 330~660 | ||||

| CJWH65 | 62.7 | 24~68 | 600 | 160 | 1224 | 9 | 400~800 |

| 900 | 220 | 9 | 550~1100 | ||||

| CJWH75 | 71.4 | 24~68 | 600 | 250 | 1990 | 9 | 550~1100 |

| 800 | 315 | 9 | 800~1600 | ||||

| CJWH85 | 81.4 | 24~68 | 600 | 315 | 2713 | 9 | 800~1600 |

| 800 | 450 | 9 | 1100~2200 | ||||

| CJWH95 | 93.5 | 24~68 | 600 | 500 | 4131 | 9 | 1250~2500 |

| 700 | 600 | 9 | 1500~3000 | ||||

| CJWH110 | 110.6 | 24~68 | 500 | 630 | 6346 | 9 | 1500~3000 |

| 600 | 800 | 9 | 2000~4000 | ||||

| CJWH120 | 120.6 | 24~68 | 500 | 900 | 8705 | 9 | 2250~4500 |

| 600 | 1000 | 9 | 2500~5000 | ||||

| CJWH135 | 132.5 | 24~68 | 400 | 900 | 11586 | 9 | 2250~4500 |

| 500 | 1200 | 9 | 3000~6000 | ||||

| Note:The specifications are subject to change without prior notice. | |||||||

Related news of Main Parameters for CJWH Middle Torque Series Twin Screw Extruders

Related products

-

Waste plastic or Modified PE Pelletizing

Contact UsThe waste plastic or modified PE material is fed into the machine through a hopper. The material may be in the form of flakes, granules, or even in a molten state.

-

OPTIMIZING CROSS CUT SAW MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

LFQ1300 Micro Computer Controlling Slitting Machine

Contact UsLFQ1300 Micro Computer Controlling Slitting Machine

-

Capacity 1800ML Aseptic Bottle Suitable For Krones Machine

Contact UsBottle Volume: 1800ml

Bottle Type: Aseptic-filling bottle

Suitable Equipment: Krones

Packing Method: Standard packing for export.

Reviews

There are no reviews yet.