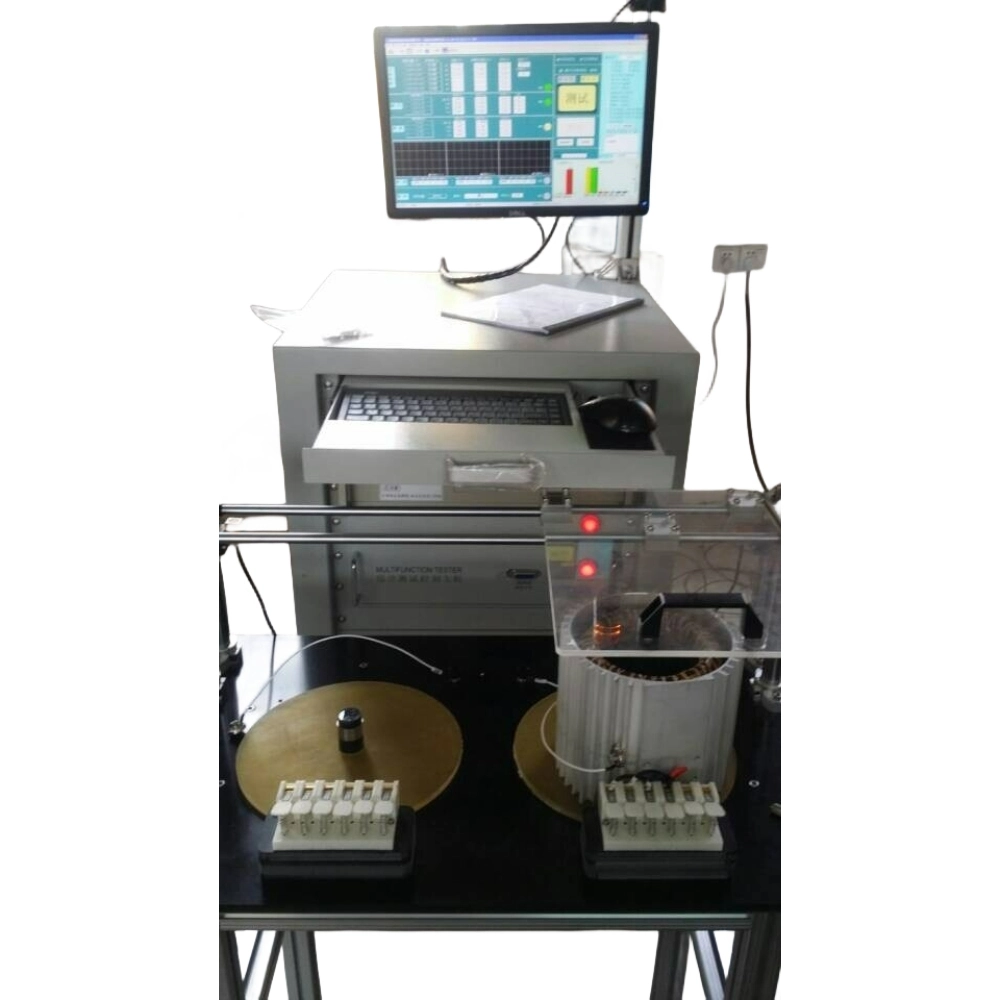

FS-400 stator test bench

The motor stator comprehensive testing system integrates DC resistance testing, inductance testing, power frequency withstand voltage testing, insulation resistance, inter-turn insulation, steering and coil anti-embedding testing functions, and is suitable for testing motor coil products.

The motor stator comprehensive testing system integrates DC resistance testing, inductance testing, power frequency withstand voltage testing, insulation resistance, inter-turn insulation, steering and coil anti-embedding testing functions, and is suitable for testing motor coil products. The main features are as follows:

·All electrical performance testing items such as micromotor DC resistance and inductance testing, insulation resistance, power frequency withstand voltage, inter-turn insulation, de-embedded testing, etc. can be completed automatically and at high speed at one time.

·The parameter determination criteria of the standard motor catalog are set. If the test result data exceeds the standard, the equipment will automatically sound and light alarm, with NG/PASS display judgment, which is convenient and fast.

·The unique fully automatic range conversion tracking test function has higher full-range test accuracy than other similar instruments.

·The inter-turn withstand voltage test function with any impact mode and repeated impact times, automatic and multi-waveform corresponding discrimination, can observe the rising edge and peak waveform mutation in real time, and automatically detect various forms of poor insulation between coil turns.

·The power frequency and inter-turn test voltages can be set arbitrarily to automatically generate and stabilize the voltage. The test data is not affected by the voltage fluctuation of the external power grid. It can automatically offset the inherent leakage current of the test system and automatically monitor and confirm the effective status of the high-voltage test.

Related Products

Motor temperature rise test bench

Motor temperature rise test bench 2

AC and DC motor testing system

New energy performance test bench

Electric vehicle motor dynamometer

Related products

-

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

-

VMC 700 CNC Vertical Milling Center

Contact UsThe three axes are designed with direct drive,high inertia motor with large lead screw, three axes acceleration up to 1G, from standstill to 48m/min, just 0.2 seconds.Standard 21 servo tool changer.

-

Waste PE PP HDPE LDPE Plastic Bags Recycling Pelletizing Machine Line Plant

Contact UsPlastic Pelletizing Line is applicable to the rapid granulation of PE, PP, LDPF, HDPE Film, Bags, Bottles and other plastic raw materials and wastes. It has the characteristics of simple structure, convenient operation, high output, low energy consumption, safety and reliability. The output of our granulator ranges from 100 kg to 1000 kg per hour. Our machines can be customized according to your requirements.

-

3MG132G CNC automatic track grinder for ball bearing inner ring

Contact UsType: high precision bearing grinder

Abrasives: diamond wheel

Controlling Mode: CNC

Processing Mode: fully automatic

Precision: high precision

Certification: GS, CE, ISO 9001

Customisation: upon request

Place of Origin: Wuxi, China

Machining Accuracy Grade: P4/P5

External Dimensions: 2070mm*1320mm*1880mm

MOQ: 1 set

DM: 3 months

Packaging: three-ply board

Reviews

There are no reviews yet.