WE67K-50/1500 Small CNC Press Brake

The model of this cnc press brake is ZDPE-5015 (WE67K-50/1500),with ZD-58 CNC control system,linear encoder,back gauge servo motors and other accessories are installed for perfect machine performance.

https://www.zdmt-machine.com/we67k-50t1500-small-cnc-press-brake.html

The model of this cnc press brake is ZDPE-5015 (WE67K-50/1500),with ZD-58 CNC control system, linear encoder, back gauge servo motors and other accessories of famous brand are installed for perfect machine performance.

Main Features

▪ Advanced proportional valve controls the hydraulic cylinders to work synchronously and achieve precise repeatability performance.

▪ Be capable of be controlled at random point within the stroke.

▪ Repeatability precision +/-0.01mm,parallelism precision +/-0.02mm.

▪ Deflection compensation table for high precision.

▪ ZD-58 CNC together with linear encoder, DP-TECH hydraulic system and other famous brand elements to ensure excellent performance.

▪ Quick clamps is for easy operation of removing and changing upper punch tools.

▪ X axis is controlled by servo motor,with strong synchronous belt,with high control accuracy,fast positioning and low noise.

▪ The backgauge installed with ball screw and linear rail,with high repetition accuracy and low maintenance.

Application

The application scope of press brake machine is very wide and they can be used in multiple industries and scenarios :

1. In the mechanical manufacturing industry, such as the processing of body panels in the automotive manufacturing industry;

2. Forming treatment used in the construction industry for manufacturing metal structural components such as railings and doors and windows;

On the electronic and electrical production line, it can be used for bending and shaping circuit boards as well as shaping and fixing coils, etc.

The production of various sheet metal parts in the hardware products industry also cannot do without the application of bending machines.

In fields such as aerospace, professional bending techniques are also required to process and shape special materials. In addition, bending machines can often be seen in some traditional industries such as light industry and textiles. In general, in any situation where thin metal sheets need to be bent, the application of a bending machine may be involved.

Main Specifications

| Model | 50/1500 | 70/2500 | 110/2500 | 110/3200 | 110/4000 | 130/3200 | 130/4000 |

| Bending force(KN) | 500 | 700 | 1100 | 1100 | 1100 | 1300 | 1300 |

| Bending length (mm) | 1500 | 2500 | 2500 | 3200 | 4000 | 3200 | 4000 |

| Columns distance (mm) | 1100 | 2050 | 1950 | 2650 | 3100 | 2650 | 3100 |

| Throat depth (mm) | 300 | 400 | 400 | 400 | 400 | 400 | 400 |

| Stroke (mm) | 150 | 170 | 200 | 200 | 200 | 200 | 200 |

| Open height (mm) | 340 | 360 | 385 | 385 | 385 | 385 | 385 |

| Main motor (kw) | 5.5 | 5.5 | 7.5 | 7.5 | 7.5 | 11 | 11 |

| Dimensions (mm) | 2100x1700x2200 | 3100x1800x2360 | 3200x1800x2650 | 3800x2000x2650 | 4800x2000x2700 | 3900x2100x2670 | 4800x2100x2700 |

| Weight (kg) | 2000 | 4800 | 6200 | 7000 | 8000 | 7300 | 8200 |

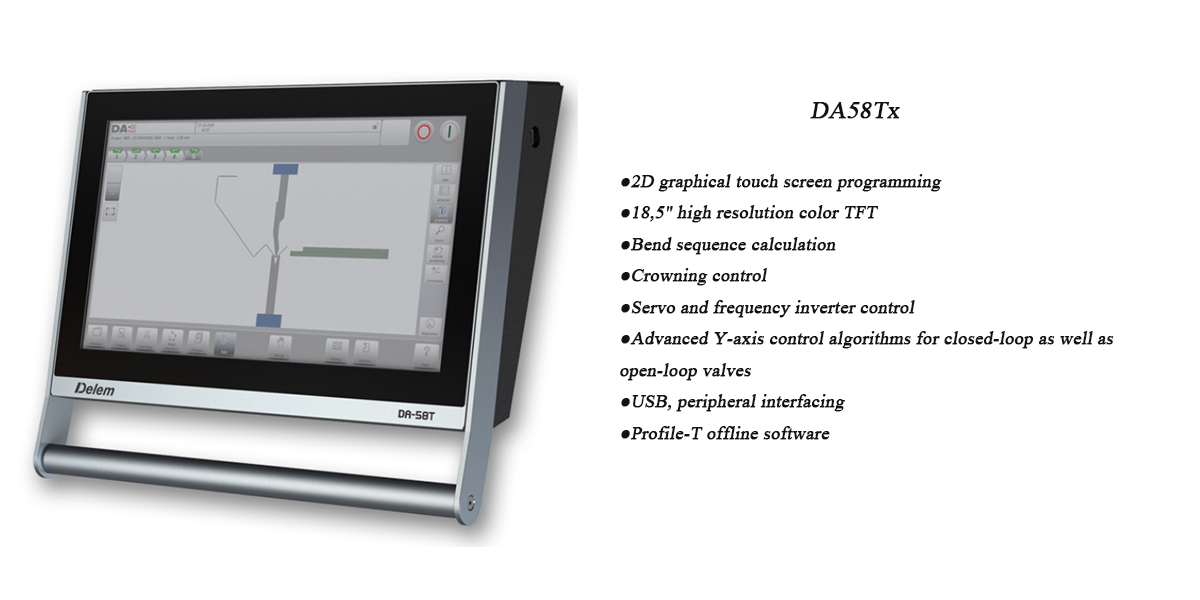

Optional control system

Company Profile

Related products

-

Used NSC Schlumberger GC14 Gilling Machine

Contact UsYear: 1996

Spinning production line

Mixed strip: GC15 barrel diameter 1000 * 1200mm, 1 head and 1 barrel, automatic barrel change

One stitch: GC14 cylinder diameter 1000 * 1200mm, 1 head and 1 barrel, with self leveling and automatic barrel changing

Two needles: GC14 cylinder diameter 700 * 1200mm, two heads and two barrels, automatic barrel changing

Three needles: GC14 cylinder diameter 600 * 1200mm, 4 heads, 2 barrels, automatic barrel change

According to your requirements, we can transform it into a suitable size for your production needs! -

FSH-FMI2020-B Standard Single/Double Channel Fluid Injection

Contact UsFSH – FMI2020 – B standard series of high-precision fluid dispensing / refilling system consists of a digital control box, stepper motor and one to two high precision rotary ceramic pump modules driven by step motor.

-

Water-cooled cabinet

Contact UsThe water-cooled cabinet condenser uses a water-cooled condenser, and the evaporator directly cools the air.

-

Small Scale PE PP HDPE LDPE Films Bags Rigid Plastic Granulators Recycling Pelletizing Machine

Contact UsThis is multifunctional small plastic pelletizing line. It is used to recycle various plastic leftovers, such as PP, PE, HDPE, LDPE, PVC, PLA, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

Reviews

There are no reviews yet.