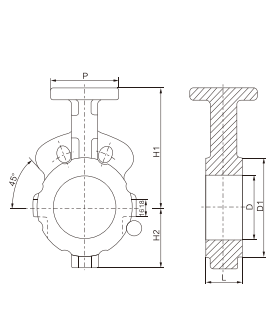

Pneumatic Clamp Soft Seal Butterfly Valve

Nominal Diameter:DN40~300mmFlange Size:JIS-10K、ANSI-150LbMax Operation Pressure: 1.6MPaUsing Temperature Range:-10’C~200℃Leak

Product model: D671FG

Nominal pressure: PN0.6-1.6MPa

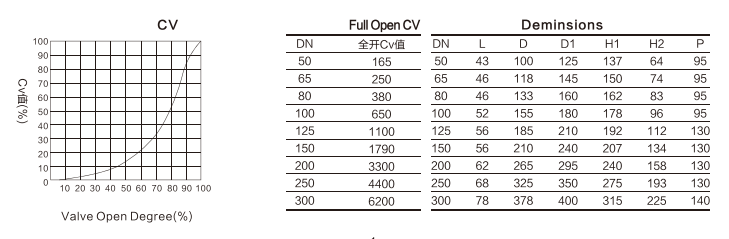

Nominal diameter: DN50-DN300mm

Applicable temperature: -10-200 ℃

Product Material: QT450, Stainless Steel

Applicable media: ordinary acid-base, water, oil, etc

Product model: D671f-10Q/C/P

Nominal pressure: PN0.6-1.6MPa

Nominal diameter: DN50-DN300mm

Applicable temperature: -10-200 ℃

Product Material: QT450, Stainless Steel

Applicable media: ordinary acid-base, water, oil, etc

Related products

-

UT 1.6523/8620/20CrNiMoA Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Blockund Bar

Contact Us1.6523 Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Block/Round Bar

-

VMC 700 CNC Vertical Milling Center

Contact UsThe three axes are designed with direct drive,high inertia motor with large lead screw, three axes acceleration up to 1G, from standstill to 48m/min, just 0.2 seconds.Standard 21 servo tool changer.

-

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

-

Small Scale PE PP HDPE LDPE Films Bags Rigid Plastic Granulators Recycling Pelletizing Machine

Contact UsThis is multifunctional small plastic pelletizing line. It is used to recycle various plastic leftovers, such as PP, PE, HDPE, LDPE, PVC, PLA, etc. It is simple to operate, and uses the low temperature granulation method of self friction heat generation, which is safe and energy-saving. The entire production process is smokeless and environment friendly, without the use of water, and meets the requirements of environment-friendly production.

Reviews

There are no reviews yet.