KSDC-8604A/A1 Centralized Dust Collector

Features:

● Compact and reasonable structure design

● Convenient dust removal, fully automatic dust removal, to ensure the continuity and efficiency of production

● Dust collection, container loading and unloading is convenient, the connection with the filter funnel is sealed, no dust leakage

● Intelligent control, optional automatic inverter, remote linkage function

● PLC control system control, humanized design of operation panel, easy to use

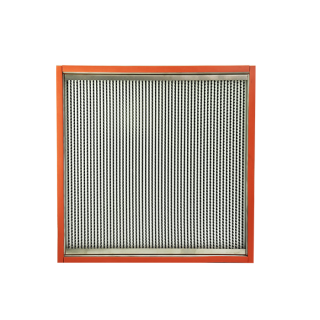

● The imported high-quality polyester filter material is used, and the surface of the filter material is covered with a high-precision PTFE membrane, which has higher filtration accuracy and higher filtration efficiency

Introduction:

86 series central dust collectors are the second generation of Kaisen centralized dust collector, which is more versatile. Upgraded PLC system supports multi-languages and easy to operate. Meanwhile, its compact design, small foot-print and high filtration efficiency are also favored by many laser machine manufacturers at home and abroad.

Parameters:

|

Model |

KSDC-8604A/A1 |

|

Fan Air Flow |

6500/8200±300 m3/h |

|

Inlet Air Flow |

4500/6800m3/h |

|

Motor Power |

5.5/7.5kW |

|

Power Supply |

3x380V/50Hz |

|

Filter Material |

Polyester + PTFE |

|

Filtration Area |

60㎡ |

|

Filtration Efficiency |

≥99.9% |

|

Filtration Precision |

≥0.3um |

|

Filter Cartridge |

4 Pcs |

|

Cleaning Method |

Automatic cleaning |

|

Compressed Air |

0.5~0.6Mpa |

|

Noise Level |

≤72±5 dB |

|

Dimension (WxDxH) |

1100×1100×2750mm |

|

Weight |

750±20kg |

Options & Accessories:

Independent electric control cabinet

Frequency converter

Explosion proof device

Anti-static filter cartridge

Ducting accessories

Spiral duct

Applications:

Multi-uints welding central dust collector

HAN'S Laser cutting dust collector case

Robot welding house fume disposal solution

Steel pipe plasma cutting disposal solution

ATEX Type central dust collector case

Plasma cutting dust collector case

Related products

-

PP Rainwater Module Heavy-duty 60T(Blue)

Contact UsXihai Since 2013, it has been dedicated to the rainwater industry.It is a leading professional service provider for sponge cities in China.

-

LUFH Laminar Airflow System

Contact UsLaminar flow is an air purification device that provides Class A unidirectional flow and creates a locally high cleanliness environment.

-

NGB High Temperature-resistant 350℃ Separator HEPA Filter

Contact UsThe filter material is high temperature resistant ultra-fine glass fiber filter paper, and the separator is aluminum foil corrugated sheet.

-

KSXH-20B Soldering Fume Extractor

Contact UsFeatures:

● light weight, easy to operate

● Adjustable flexible POM suction arm

● High-power DC brush-less motor

● Multi-level-filtration,cotton filter, HEPA filter and activated carbon filter

● Long service life, low noise, large air flow

Reviews

There are no reviews yet.