The SWIFT handheld loose cable tie machine is a high-efficiency and convenient automatic bundling device designed to enhance productivity and reduce labor costs. It is suitable for bundling cables, wire harnesses, pipes, and other applications, making it widely used in electronics, appliances, automotive wiring, packaging, and other industries.

Key Features:

Efficient Bundling: Automatically feeds, tightens, and cuts the cable tie in one second, significantly improving work efficiency.

Portable Design: Lightweight and easy to operate, making it adaptable to various work environments.

Strong Compatibility: Supports different sizes of loose nylon cable ties to meet diverse bundling needs.

Stable & Durable: Made with high-quality materials and advanced technology for long-term reliable performance.

This machine enhances automation on production lines, reduces manual errors, and ensures product consistency, making it an ideal bundling solution for industrial applications.

Related products

-

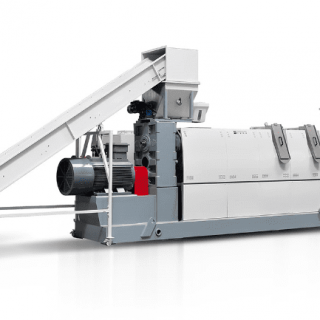

Waste plastic or Modified PE Pelletizing

Contact UsThe waste plastic or modified PE material is fed into the machine through a hopper. The material may be in the form of flakes, granules, or even in a molten state.

-

Optimizing Cross Cut Saw MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

OPTIMIZING CROSS CUT SAW MAXCUT F18S+SENSIT 005

Contact UsHigh speed optimization Timber cutting optimizing Cross-cut saw and precision cutting

Automation production line. -

UT 1.6523/8620/20CrNiMoA Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Blockund Bar

Contact Us1.6523 Cold Drawn Bar Cold Drawn Bar Alloy Steel Round Bar/Flat Bar/Steel Block/Round Bar

Reviews

There are no reviews yet.