Double Station Blow Molding Machine

● Suitable for producing 1-5L different size of gear oil bottle, lubrication oil bottle, cooling water tank etc. ● Optional multi-layer co-extrusion. ● Optional view strip line system

Technical parameters

| Model | Unit | BM05D | BM12D | BM20D |

| Max product volume | L | 5 | 12 | 20 |

| Dry cycle | Pc/h | 700*2 | 600*2 | 600*2 |

| Die head structure | Continuous type | |||

| Main screw diameter | mm | 75 | 90 | 90 |

| Max plasticizing capacity (PE) | kg/h | 90 | 160 | 160 |

| Driving motor | Kw | 30 | 45 | 45 |

| Oil pump motor power(Servo) | Kw | 15 | 18.5 | 18.5 |

| Clamping force | KN | 70 | 120 | 160 |

| Space between platen | mm | 150-510 | 240-640 | 280-680 |

| Platen size W*H | mm | 420*390 | 520*490 | 500*520 |

| Max.mould size | mm | 420*400 | 540*500 | 560*520 |

| Platen moving stroke | mm | 450/520 | 600/650 | 650 |

| Heating power of die head | Kw | 7.5 | 10 | 12.5 |

| Machine dimension L*W*H | m | 3.7*3.1*2.7 | 4.2*3.2*3.0 | 4.3*3.2*3.1 |

| Machine weight | T | 8.5 | 12 | 14 |

| Total power | Kw | 60 | 90 | 93 |

| Note: Informations listed above are for reference only, the production line can be designed by customer's requirements. | ||||

FAQ

1. Q: Why should you choose Suzhou Jwell?

A: We follow Germany type of business heading as the worldwide reliable supplier of plastic extrusion line. We have already provided more than 5000 lines located in all countries because we are providing the lastest technology, qualified machine, reliable component and best after-service. 300 Engineers are travelling in the world throughout year for installation and test of machine, the after-service are free and availble forever. That's why we grow up from 10 staff company to 3500 staff Pioneer of Chinese extrusion machine supplier. Our products are spread all of China and also export to Russia, India, Korea, Indonesia, Middle East, Africa and south America, Spain, Italy, ect. We are received good appraisement from them.

“Excellent Quality and Perfect Product” is JWELL quality guidance, is the direction of the whole company’s member.

“Honesty” is our core thought to make “ Long life JWELL”.

2. Q: How much does it cost?

A: Please fill in your specific requirement in the bottom blank and sent to us, so that we could make a detail quotation for you.

Related products

-

Oxygen Rich Side Blown Melt Melting Furnace

Contact UsThe oxygen rich side blown molten pool melting furnace is an efficient and energy-saving steel melting equipment. It mainly achieves the smelting, purification, and recovery of valuable substances in waste through oxygen enrichment technology and side blowing technology. Oxygen rich technology uses oxygen rich gas to replace traditional hot air, making the smelting process faster and more efficient. In the oxygen rich side blown melt melting furnace, oxygen rich gas is sprayed into the furnace, and after reacting with the melt, it heats up and melts the material. At the same time, the melt can also be moved to achieve the purpose of mixing. Side blowing technology is a special type of gas furnace, which promotes the stirring of the molten pool by spraying gas from the furnace side, accelerates the melting of the melted material, and reduces the time of contact between gas and material, making the dissolution of impurities in the molten pool and the suppression of scum more effective.

-

General Rotogravure Printing Machinegghgh

Contact UsOur Printing Machine is a high-quality printing device that is designed to meet the printing needs of various industries. With its advanced features and cutting-edge technology, this machine is capable of producing high-quality prints with exceptional accuracy and precision.Our Printing Machine is a high-quality printing device that is designed to meet the

-

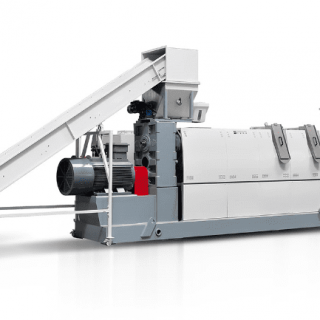

Waste plastic or Modified PE Pelletizing

Contact UsThe waste plastic or modified PE material is fed into the machine through a hopper. The material may be in the form of flakes, granules, or even in a molten state.

-

Used NSC Schlumberger FM7N Spinning Machine

Contact UsThe company was established in Zhangjiagang, Jiangsu, China in 2005 .Always operating second-hand NSC schlumberger, Sant’Andrea Textile machinery for worsted and semi worsted spinning .

Reviews

There are no reviews yet.